Pendant Automation Diary – Startup and Commissioning Skills

Three Key Startup and Commissioning Skills

I visited a project site last week where Pendant is in the startup and commissioning phase. The project is a sizable return center with lots of conveyor and merges and sorts. Soon, a lot of people in the facility will process returned merchandise. During the couple of days I was on-site, it was clear that there are some startup and commissioning skills beyond the technical that are critical to success.

In an earlier post https://www.pendantautomation.com/startup-and-comm…g-what-to-expect/, we wrote about what you should expect during the startup and commissioning phase of a control systems integration project for conveyor handling. It is a complicated process, with plenty of chances to make mistakes. It’s necessary for your control systems integrator to know their stuff technically, but that’s not sufficient. Here are three things that make the difference between a technically correct startup and a great startup phase:

Diligence

At this particular site, there are over 175 processing stations. At each station, an operator receives returned goods and uses the software system to triage the goods. The operator places the goods in the correct color-coded totes. Then he puts the totes onto the conveyor system for sortation and the ultimate disposition of the goods. Operators do this repeatedly for the duration of their shift.

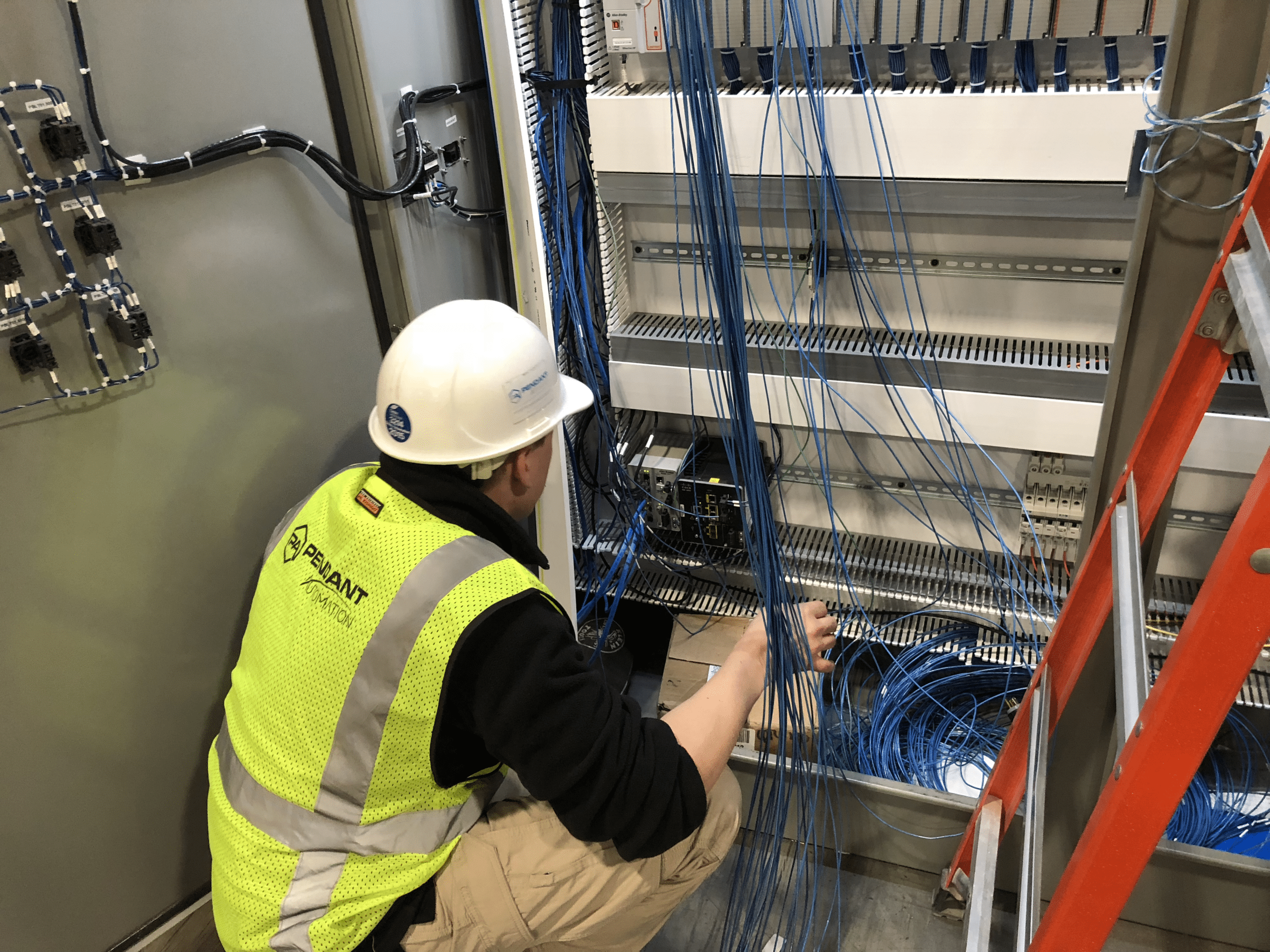

Eight conveyors take goods from the processing stations and feed the main sortation conveyor, which has to merge the goods from the eight conveyors prior to sorting. The merchandise is sorted according to whether it can be resold, refurbished, placed into inventory, or destroyed. It’s a lot to keep track of for the control systems integrator, who has designed the control system, built the control panels, and programmed the PLC. There are photo eyes everywhere to keep track of the product as it moves. Other photo eyes monitor whether lanes are full or jammed. There are emergency stop pull cords and pushbuttons, lane full beacons, jam beacons, start/stop stations, jam reset stations, audible horns, scanning cameras, and miles of electrical conduit.

If you make the mistake of hiring a control systems integrator that is not diligent and organized, you’re begging for disaster.

Patience

Patience is sometimes thought of as a dirty word in business. Some people confuse patience with a lack of a sense of urgency. In the case of a startup, patience is most definitely a virtue.

The startup and commissioning environment is one where there is a lot of unfinished business. Mechanical installers are on site, installing conveyor, racks, operator stations, safety equipment, and other mechanical equipment. Electrical installers are also on site, connecting miles and miles of wires throughout the facility. It’s not always going to go in the sequence you expect, nor at the time you expect.

During startup and commissioning, your control systems integrator will be testing the system by turning on the conveyors and using totes to see if what happens is what is supposed to happen. Did the totes merge efficiently and without jams? Did the totes sort properly and end up in the right place? Is the throughput high enough? Does timing need to be adjusted in the program?

Now imagine trying to do all that while other people who have their own, sometimes competing priorities, are working on, in, and around the same system you are testing. This makes patience one of the most critical of the startup and commissioning skills.

Perseverance

The last of the startup and commissioning skills is probably obvious after you read about the first two. If you are the integrator, you are dealing with a complex system and a lot of what you could call interference. It’s inevitable that something is not going to work the way it should. That’s where perseverance comes in.

During one of the tests while I was onsite, we ran hundreds of totes on the main conveyor. All except one tote sorted correctly during that test. In such a situation, it would be easy to say that one missorted tote out of hundreds is good enough. But a great startup and commissioning tech is dying to know why that tote didn’t sort, and will tweak things and run the tests again until it’s correct.

One of the tests we ran was actually a repeat of a test completed two weeks earlier. There were some intermittent but not debilitating problems with a jammed lane in the earlier test. We reproduced the jam condition, tweaked the program, and eliminated the problem.

You should be sure to hire a control systems integrator that believes the system should function at peak efficiency and accuracy. Their perseverance during startup will pay off for years and increase your return on investment.

In retrospect, it may be sloppy usage to refer to these three startup and commissioning skills as “skills”. Maybe they more accurately describe the makings of the “personality” or the mindset of your control systems integrator. In any case, be sure that they bring these traits to your job, every day, to get the most out of your new automation system.

I would like you to diligently and patiently persevere through my next startup