PLC Control for Manufacturing

The Debate

A Google search comparing PLC/SCADA systems to a DCS approach yields over 500,000 results. PLC vs DCS Google search

Many of the articles in this search attempt to make comparisons of DCS systems with PLC systems. In some cases, the author effectively simplifies the comparisons into a few key points. But the decision is complex and highly dependent on specific circumstances. There is not an easy answer, because each project is different.

The decision is not just technical, and consequently the amount of available capital is a critical factor. It’s important to understand the point at which the next upgrade in functionality becomes costly enough to decrease the return on investment.

In this post, we’re not going to add our opinion. Instead, we will share some of our experiences using the PLC-based approach in manufacturing processes, both discrete and continuous.

PLC Capabilities

Although the majority of Pendant’s projects are in the conveyor and material handling industry, over the years Pendant has completed many projects in the discrete manufacturing and process industries. In 2018 we have some large projects on the books in manufacturing operations, combining batch and continuous production.

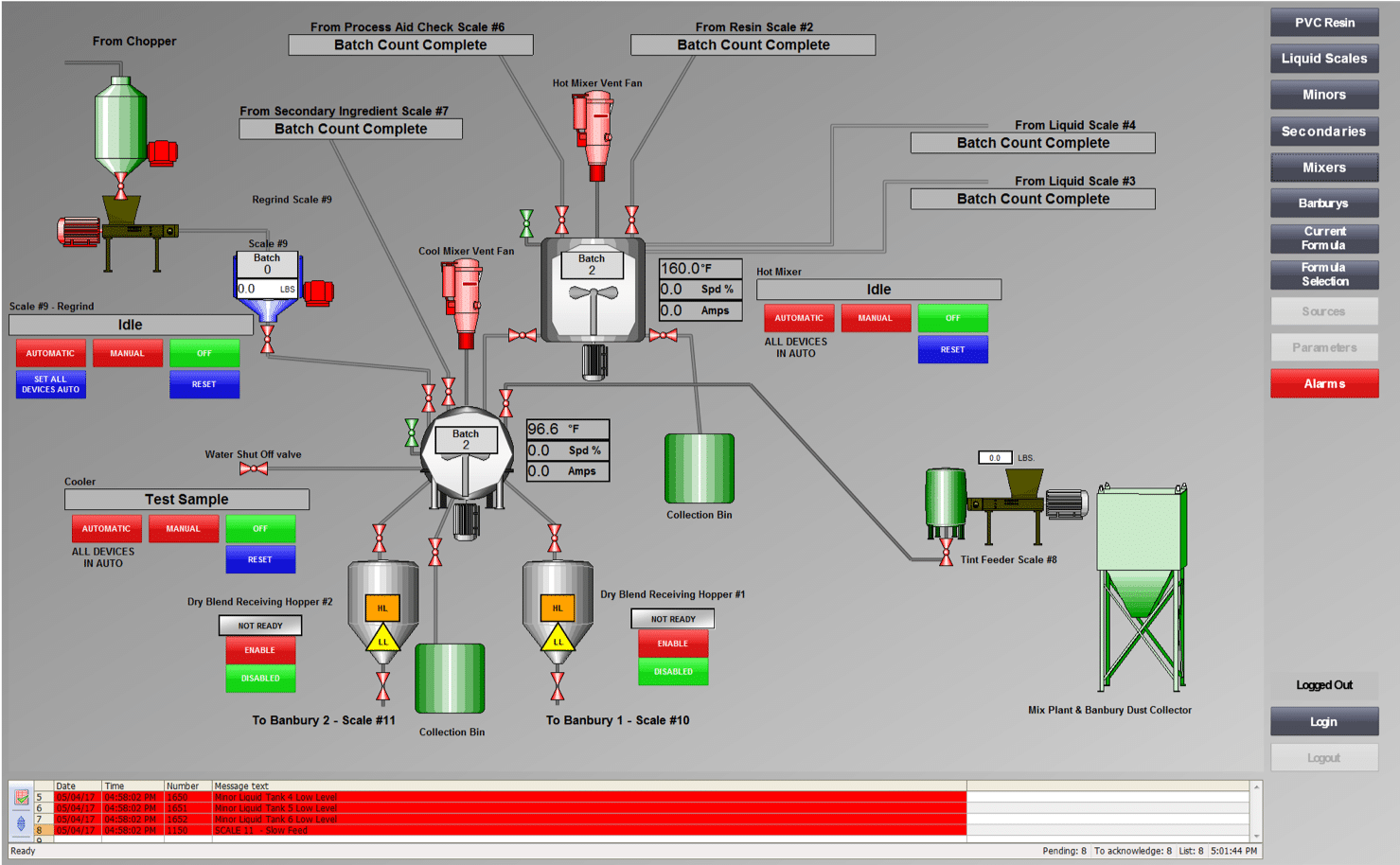

The specific capabilities that we include in these types of projects can be more complex and sophisticated. The photo above, a single screenshot from an operator station we programmed as part of a large manufacturing project, is one example.

Some of our current projects include features like:

- PID (proportional integral derivative) function blocks for controlling temperature, pressure, and flow.

- Historian functionality to collect, manage, and analyze process data.

- Consumption reporting.

- Networked PLCs .

- In line weighing and batching. Recipe control

- Interfacing with the inbound rail system.

-

Remote viewing

-

Motion/servo controls.

You may incline to towards solutions with which you have prior experience. If you have not considered a PLC control system in the past, for your next project familiarize yourself with alternatives. You may find that a PLC-based control system is perfect for your project, especially when you consider value for your investment. We will be pleased to share with you ways in which you can utilize the constantly evolving PLC for your control systems.